Common Myths, Fallacies And Misconceptions In Electromagnetic Compatibility And Their Correction

D. A. Weston

EMC Consulting Inc.

10-12-2019

These are some of the commonly held beliefs about EMC which are either a mistake in reasoning, untrue, only partially true (i.e. with many exceptions), without foundation, or based on misunderstanding. EMC is indeed a complex issue in which all aspects of an EMI or EMC engineering situation must be considered in order to arrive at the correct solution. The goal of this article is to help clarify some of these situations.

Over a period of 38 years of EMC experience, and particularly during the presentation of seminars, these are the myths and fallacies which I hear over and over again. This article is intended primarily for the practicing electronic engineer or technician, who is not a specialist in the field of EMC/EMI or someone starting out in EMC. It is presented in the hope that the explanations and clarifications may be of practical use to the reader.

1.) EMC/EMI is black magic

Based on my experience, this is the most common comment made about EMC. We often use the term magic when describing an unexpected or unusual result.

The term magic is used to describe astonishing results as at a magic show, when sound engineering is often the basis of the magic trick. This may also be applied to some aspects of EMC. Often the results of an EMI test, after inclusion of EMI mitigation or EMC engineering components, is contrary to what is expected, and sometimes counter intuitive.

For example: shielding against magnetic fields using thin materials with a relative permeability of 1 seems like magic but has a simple explanation as described in references 1, 3, 4, and 5.

The major reason EMC is seen as magic is a lack of understanding of the underlying principles. Also the coupling mechanism in an EMI problem may not have been identified or a number of coupling mechanisms apply. Often the paths that RF currents take are not always obvious and parasitic components in a circuit have been ignored.

Often many sources of emissions exist and when one has been minimized a second predominates. This often means that a fix is less effective than expected.

Minor changes in PCB layout, component type or even make, lead length, location, and mechanical assembly can lead to dramatic RF changes.

2.) Cable shields must be connected to ground at one end only

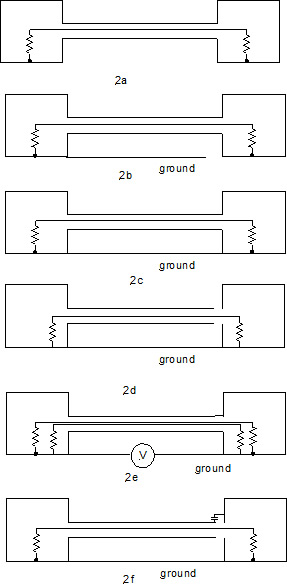

When a shielded cable is connected between two or more pieces of equipment contained in conductive enclosures the shield should be thought of as an extension of the enclosures as shown in 2a. Therefore the most effective grounding is as shown in 2a or 2b, where one or both enclosures are isolated from chassis.

This is often impractical and for safety and grounding philosophy reasons the enclosures are often grounded at both ends as shown in 2c.

The common mistake is to assume that one end of the shield should be isolated from the enclosure as shown in 2d and not the enclosure from ground. This results in only E field shielding, limited shielding of plane waves when the cable is many wavelengths long, and no appreciable magnetic field shielding.

The most common reason given is to avoid ground loops. However other techniques are available and a well thought out grounding philosophy, backed up by a power and grounding diagram , should be used.

High power and RF current should be routed on return conductors which are isolated from chassis at one end and do not use the shield as a return path.

Connecting the shield to chassis at one end via a capacitor reduces current at low frequency but provides an RF ground. This is seldom as good as a solid conductive connection but is often good enough. In EMI problem solving where the problem frequency is known the capacitor may be made to resonate using its own parasitic inductance plus any PCB trace and via inductance.

If, however, cables are routed over long distances or over grounds that carry high RF currents different ground potentials may exist , as shown in 2e, and this is often the reason given for disconnecting the shield of the cable from the enclosure as shown in 2d.

If the noise currents on the shield are dc or at power frequencies then an RF capacitive ground connection to the enclosure, as shown in 2f, will shunt RF currents but present a high impedance to low frequencies. The correct implementation of the capacitance or capacitances and their connection to ground is important to achieve a low impedance. In one case wrapping foil around the insulation of the cable as it entered the shielded enclosure formed a high quality capacitor. It was this outer foil that was bonded to the enclosure at the input point.

Another approach is to use a differential signal and receiver. Then the voltage induced in the center conductors as shown in figure 2e is common mode and will be reduced by the Common Mode Rejection Ratio of the receiver.

There is a practical limit to the shielding effectives of a shielded cable, depending on the type of shield, shield termination technique, and type of connector and backshell. Reference 1 section 7 pages 357-430 describes these effects. When shields are terminated to a backshell using the ubiquitous “pigtail” then the level of shielding can be severely compromised, see reference 1 pages 416-417.

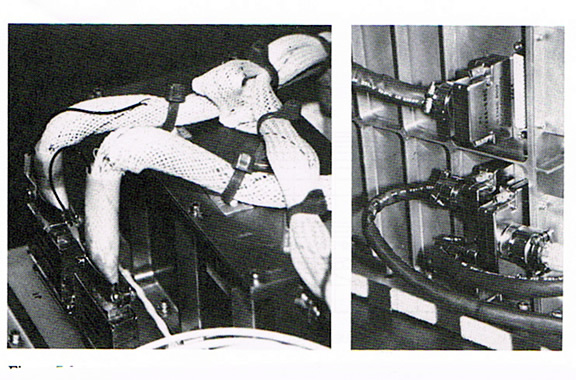

The pigtail is shown on the left hand side of figure 1, the shielding effectiveness above some frequency is no higher than an unshielded cable. Whereas the cable terminated with a Glenair EMI backshell, shown on the right hand side of figure 1 has a very high shielding effectiveness.

Figure 1. Left hand photo of pigtail. Right hand photo EMI backshell

Consider the single sided signal, low frequency magnetic field shielding effectiveness (SE) of the cable configuration in figure 2c, where each enclosure is grounded, compared to that in figure 2d where the shield is unterminated at one end. The magnetic field causes current to flow in the shield of 2c, whereas in 2d the current flows on the center signal conductor/s. Thus the attenuation achieved by 2c appears to be simply the ratio of the load and source impedance in the unshielded 2d configuration to the dc resistance of the cable shield in 2c.

However the current induced in the cable shield by the incident magnetic field is much higher in figure 2c than in the center conductor signal wire in figure 2d. This means that up to about 1kHz the shielded cable shielding effectiveness is approximately zero. Above 1kHz the current induced into the shield of the cable decreases and the voltage drop in the shield is a function of its transfer impedance. Transfer impedance is defined as the voltage developed between the inside of the shield and the center conductor/s divided by the shield current.

For a typical shielded cable/conduit the magnetic field SE is 16dB (numeric 6.3) at 100kHz and 36dB (numeric 63)at 1MHz. Reference 2 describes this further.

Figures 2a to 2f

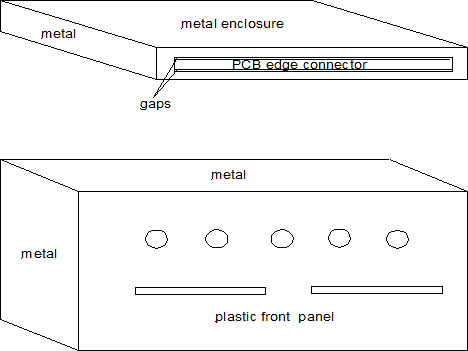

3) An enclosure with less than six conductive sides around equipment provides electromagnetic shielding.

If an enclosure has one to five sides left open, has a long gap or some sides are of a non-conductive material, as shown in figure 3a, then no magnetic field or plane wave shielding is achieved by the enclosure and only limited E field shielding is provided. The level of radiation may even increase with such a shield! For adding a partially shielded enclosure changes the radiation pattern from the equipment and so instead of radiating equally (isotropically) in all directions the radiation is confined to the open sides. It is this change in directivity that can often result in increased radiation with the partial enclosure.

If enclosure and gap resonances occur then the field with the partial enclosure may be significantly higher than no enclosure.

Sometimes engineers find that the radiated emissions from such a non perfect shielded enclosure do change, and sometimes improve, compared to a non conductive enclosure, but this is not due to any improvement in shielding. Adding a metal surface such as a wall of an enclosure close to a PCB or wiring adds an image plane, which often reduces emissions from the wires or PCB, especially when the PCB ground plane is less than perfect.

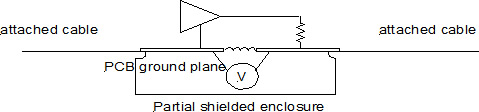

A major source of common mode noise currents on cables is RF noise voltages developed on PCB and backplane ground planes as shown in figure 3b. Connecting the PCB ground plane to a partial enclosure at the locations shown in figure 3c can reduce the current flow on cables and radiation from the cables.

A six sided box will provide magnetic field shielding even when the material, has a relative permeability of 1, e.g.. aluminum foil, or even a conductive coating on a non conductive material. This is certainly counter to accepted wisdom and the mechanism is described in references 1, 3, 4 and 5.

Figure 3a Partial conductive enclosures

Figure 3b Ground plane noise driving cables

Figure 3c Additional grounding path through partial shield reduces radiation.

Thus the effectiveness of a partial enclosure is determined by whether aperture coupling or cable radiation predominates.

4) Adding an isolated metal plate between wiring, enclosures and PCBs will add significant shielding

An isolated metal shield was placed between a PCB containing digital logic powered by an on board battery and a receiver also powered by a battery. The output signal from the receiver was made through an opto-coupler thus no electrical connection was made to either board. This shield was found to be somewhat effective at some frequencies (but not as good as may be predicted) and at other frequencies the shielding effectiveness was 0dB!

Likewise an isolated metal shield between components has also been found to provide limited shielding effectiveness and in the case of a radiated immunity test two vertical isolated metal plates with a 2-4mm gap between the two plates showed a gain (negative attenuation) of up to 10dB just behind the plates and from 0dB to 6dB attenuation at up to 20cm behind the gap. In the same test of a 0.5m x 0.5m plate with no gap the shielding effectiveness at 300MHz and 500MHz was 20dB just behind the plate, 10dB 10cm behind the plate and only 5dB at 25cm behind the plate. See reference 9.

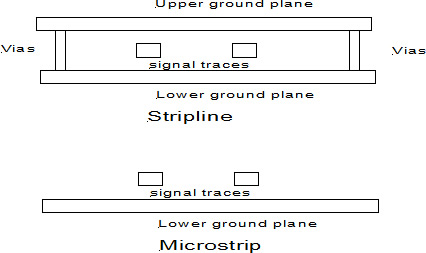

5) Making a microstrip PCB configuration (signal traces above a ground plane) into a closed stripline (signal traces sandwiched between ground planes with vias around the edges), driven single ended, will always reduce electromagnetic radiation.

A cross section through the differential configurations are shown in figure 4a

Figure 5a Cross section through a differential stripline and microstrip.

Measurements made on differential signal traces and single signal traces above a ground plane in both a microstrip and stripline configurations, described in references 6 and 7, showed the following:

The differentially driven stripline PCB with an unshielded resistive 100W load has a lower level of emissions only at certain frequencies, when compared to two differential traces close to and over an image plane (the lower ground plane). At high frequencies the level of emissions is similar. This configuration with unshielded components more accurately represents the real world. Other comparisons in the same reports between differential stripline and differential traces with image plane and unshielded loads on different PCB configurations clearly show that the stripline radiates at a lower level.

In the stripline PCB configuration that has a fully shielded load and connector, the emissions are extremely low. As the emissions from the stripline are so low, emissions from connectors, short lengths of unshielded traces outside of the stripline and ICs will predominate and the distance between the vias tacking the upper and lower ground planes has little effect on the level of radiation as the PCB is no longer the prime source.

Measurements were also made with only one trace used as the signal and the signal return connected to the ground plane in either the stripline or microstrip PCBs. We refer to this as a single sided measurement. The measurements showed that the single sided stripline with unshielded load is on average only 6dB lower than the single sided microstrip over the 50MHz to 1100MHz frequency range and from 1100MHz to 1350MHz it is up to 10dB higher!

When the major source of radiation is the PCB and not components observation of numerous PCB layouts has shown that the radiation from a PCB with full upper and lower ground planes tied together with a number of vias is invariably lower than a PCB with a single ground plane. Also a PCB with an overall ground plane and an incomplete second ground plane with small islands, is only more effective than the PCB with a single ground plane when the islands are connected to the overall ground plane using a number of vias.

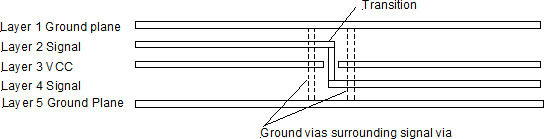

It is very important when signals transit from the far side of a PCB ground plane to the far side of a second PCB ground plane to ensure that vias connect the ground planes together as shown with a VCC plane in figure 3c. The reasons for this are many and are included in references 6 and 7.

Figure 5.c Vias connecting the ground planes together close to a signal transition.

6) If equipment is contained in a six sided conductive box (enclosure) it will meet all EMI requirements.

This common fallacy ignores the radiation from cables entering and exiting the enclosure and the weak link in an enclosure, namely seams and apertures.

When PCBs are contained in an enclosure the fields generated by the PCBs set up RF currents on the inside walls of the enclosure. The fields also couple back to the PCB and set up common mode RF currents in the PCB ground and traces. Connecting signal returns multipoint to the chassis also injects noise currents into the chassis.

Often the shield of a cable is brought through the enclosure and terminated to the inside of the enclosure. The RF current flowing on this surface then flow out on the shield. When the shield is terminated on the outside of the enclosure radiation from the shield commonly reduces significantly.

Any unshielded cable, or cable with a shield terminated on the noisy PCB ground, which exits the enclosure without filtering may have cable currents higher than with an unshielded enclosure. The reason is that the radiation from the PCB sets up currents in the inside of the enclosure which in turn generates fields impinging on the PCB. At the least the frequency of maximum radiation may change with the shielded enclosure versus unshielded.

The shield should be terminated around 360 degrees to an EMI backshell , preferably solid metal and not conductively coated plastic as shown in the right hand side of figure 1. To meet low level radiated emission limits with a braided shielded cable signal return currents on the shield should be avoided where possible or limited in magnitude. Common mode currents on the inside of the shield can be reduced using the techniques shown in figures 10b, 10c and 10d.

In many enclosures the fasteners are too far apart. Often in a thick milled enclosure gaps may appear between fasteners when the sides of the enclosure are not of the same height, see reference 1 section 6.4 page 304. For magnetic fields the size of the gap between two mating surfaces is not important. It is the length of the gap, the dc resistance and the frequency dependent contact resistance which limits the enclosures shielding effectiveness, reference 1 section 6.4.3 page 316 and reference 8.

7) A power line filter, which is effective when tested alone, will remain effective when mounted on a PCB which contains noise sources such as a switching power supply or digital components.

A power line filter which is unshielded with unshielded input power lines can have RF coupled to both the components and the input connections to the filter. This is most likely when the filter components are mounted on a PCB containing noise sources, such as switching power supplies or digital logic. The problem may be exacerbated when the input power is routed down a backplane, which is also used for digital data.

If the noisy power line is run close to the filtered power line then the resultant cross talk can either reduce the filter attenuation or even negate it completely.

Very often an effective filter capable of meeting all EMI requirements will fail conducted emission tests when unshielded and PCB mounted. If the input power lines to the equipment enclosure are unshielded a PCB mounted filter may also result in a failure in radiated emission measurements.

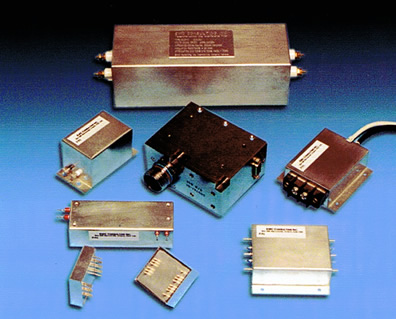

Ideally the power line filter will be shielded and mounted on the equipment enclosure wall with the input power connector mounted to the filter enclosure. All of the power line filters in figure 2 are shielded but may still suffer coupling between the input and output wiring. The filter in the center of the photo, with the connector, is mounted inside the enclosure with the connector on the outside and this configuration shows minimal coupling. If this is not feasible then the shielded filter should be mounted as close to the input power connector with shielded wires used to connect between the connector and the filter. A compromise, which may work, is to have the low frequency filtering components mounted on the PCB and additional components, which are effective at high frequency, mounted directly behind or at the input power connector.

Inductors are designed to provide an impedance to RF current and so reduce it. However when located close to a source of high field, i.e the magnetics in a switching power supply, RF current may be injected into the inductor via predominantly magnetic field, or electromagnetic coupling (see 1section 11) and be counterproductive.

Figure 7.1 Shielded power line filters

8) A power line filter with MIL-STD-220 specified performance will perform just as well as specified, when used in the real world.

A common mystery of EMC is why a power line filter with an impressive level of specified attenuation does not perform as specified when used in the real world. The reasons for this are numerous.

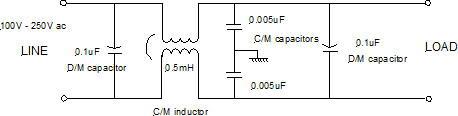

When a manufacturer of a small inexpensive filter specifies a high level of attenuation at low frequencies, the attenuation is often specified for common mode (C/M) noise voltage, and the differential (D/M) noise attenuation is not measured at all. The majority of commercial type power line filters only include C/M inductors and the only D/M component is a capacitor across the line. Thus for D/M noise, only this capacitor or other capacitors across the line are effective and the maximum attenuation is shown only for the C/M test.

A typical commercial filter schematic is shown in figure 7a. Even the most inexpensive filter is specified to a MIL-STD-220 test method. The method is designed to match test equipment to the test set up. The majority of signal generators are designed for a 50Ω load and the measuring instrument usually has a 50Ω input impedance and both are single sided i.e. not designed for differential (D/M mode) measurements. MIL-STD 220 specifies a 50Ω load and source impedance and allows an input attenuator in order to achieve this.

All LC networks exhibit a resonance frequency with a Q typically above 1 at resonance. This depends on LC values and load impedance etc, as described in reference 1 page 209. When the Q is greater than 1 the filter shows an insertion gain instead of an insertion loss at resonance and the output voltage is higher than the input, sometimes by as much as 20dB (numeric 10).

If a custom filter is designed then it may be damped as described in reference 1. In the MIL-STD-220 test method the input attenuator exhibits a series resistance, which effectively damps the resonance of almost any filter, and the insertion gain is not seen in the attenuation curve.

MIL- STD-220 allows either a C/M or D/M measurement and it is the C/M measurement that is usually described in the specification, especially if the filter only supplies C/M attenuation. The manufacturer may not mention this.

Also the signal input in the test is normally the input (line side of the filter) and the load side is used to make the measurement. Figure 7a shows the C/M capacitors on the load side and so the highest attenuation is achieved from line to load side of the filter.

In the real world the filter is often required to attenuate currents flowing out on the power line sourced by switching power supply/ies connected on the load side. The filter shown in figure 7a is not ideal for this purpose as the C/M capacitors are on the load side, whereas for load sourced noise they would be more effective on the line side.

The load impedance on a filter is rarely 50Ω even on 120V ac power lines. When the filter is used for dc power then the load impedance is typically 1 to 20Ω, which changes the attenuation characteristics of the filter. Also the source impedance of the noise voltage may not be 50Ω, as used in the MIL-STD-220 test. This is especially true of D/M noise at the fundamental or low frequency harmonics of a switching power supply.

The MIL-STD-220 test does not require a power current to flow in the filter during the test. If the filter does contain D/M inductors and is used on dc power then the value of the inductance/ies may be lower with dc current flowing.

For any of these reasons the attenuation achieved in the real world is different from the specified and often lower. The ideal filter is custom designed for the EMI test source impedance (typically a LISN) and uses the switching power supply/ies intended for the product, operated at the anticipated current draw.

Alternatively using the filter component values in SPICE, or similar circuit modeling program, with real world source and load impedances, or even switching loads, the filter performance can be evaluated. It is important to include the parasitic components described in 7.

Figure 8a Typical commercial ac power line filter.

9) A solid ground plane on a PCB or backplane used as a current return path will have an impedance in the μOhms.

When a ground plane is quoted as having an impedance in the μ Ohms this refers to its dc intrinsic or metal impedance. This is the impedance seen by an incident electromagnetic wave. However when the ground plane forms a path for RF currents, due to its inductance, the impedance will be much higher. For example from reference 1, the impedance of a 12.6cm x 10cm copper 1oz ground is 0.64Ω at 2MHz when the signal conductor is 1cm above the ground plane and 0.045Ω when the signal conductor is 1mm above it.

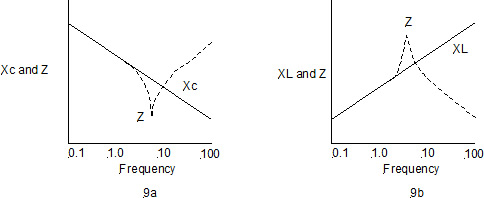

10) The impedance of a capacitor will decrease monotonically and an inductor increase monotonically with increasing frequency without limit.

This is only true of ideal components. Whereas a practical capacitor will have a parasitic inductance or equivalent series inductance (ESL). When connected by wires or PCB traces the inductance of these will add to the capacitors ESL.

A series resonance circuit is formed by the LC series components. When the capacitor is connected across a signal line, its impedance will decrease with increasing frequency and the impedance will at a minimum at resonance, rather than high frequency. At resonance, the impedance will be lower than the capacitive reactance alone.

This effect can be useful when an EMI problem frequency is known, as a low-impedance can be achieved at the resonance frequency with a lower value capacitor when the inductance is deliberately increased. For example many cell phones include decoupling capacitors at the transmit frequency/ies. A low value capacitor may be useful in minimizing attenuation of the intentional signal. Above resonance the impedance of the capacitor begins to increase with increasing frequency due to its ESL.

To achieve a low impedance over a wide frequency range a number of capacitors with different resonant frequencies may be placed in parallel. It is important to physically separate these parallel capacitors.

A practical inductor with more than a ½ turn winding will have a parasitic or interwinding capacitance between the windings. As the capacitance is in parallel a parallel resonance circuit is formed by the LC components. When the inductance is connected in series in a signal line its impedance will increase with increasing frequency and the impedance will be a maximum at resonance rather than an infinitely high frequency. At resonance the impedance will be higher than the inductive reactance alone.

This effect can be useful when an EMI problem frequency is known, as a high impedance can be achieved at the resonance frequency with a low value inductor when the capacitance is deliberately increased. A low value inductor may be required to minimize attenuation of the intentional signal. Above resonance the impedance of the inductor begins to decrease with increasing frequency due to its capacitance.

To achieve a high impedance over a wide frequency range a number of inductors with different resonant frequencies may be connected in series. Figure 9a shows the capacitive reactance of a perfect capacitor and the impedance of the capacitor with ESL.

Figure 9b shows the inductive reactance of a perfect inductor with the impedance of the inductor with parasitic capacitance.

Figure 10a Capacitive reactance and impedance with frequency and 10b inductive reactance and impedance with frequency.

11) Adding an LC filter to signal lines which exit a digital PCB will always reduce RF current flow on those lines.

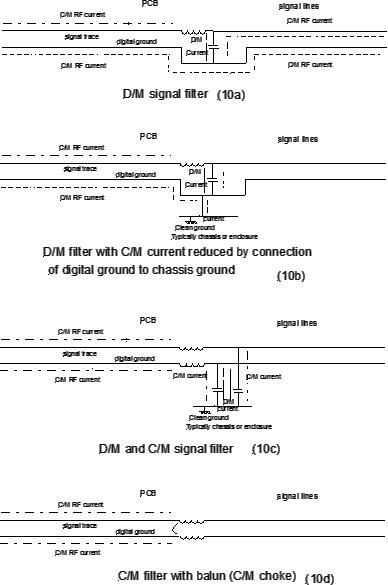

It is true that adding a low pass filter will attenuate differential mode (D/M) noise appearing between signal and signal ground. As described in section 7 of this report, any LC filter will exhibit a resonance frequency. It is common to have insertion gain at that frequency, I.e. the output voltage from the filter is higher than the input voltage! To reduce common mode noise (C/M) the capacitors must be connected to a clean, typically chassis, ground.

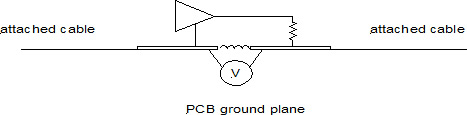

C/M noise appears on every conductor on a PCB including the ground. When the capacitor is connected to a noisy digital ground as shown in figure 10a then the currents are conducted via the capacitor to the signal lines. Removing the capacitor may actually decrease the common mode currents on the signal lines.

It is important to also include an inductor, typically a ferrite, on the signal ground as shown in 10c. If individual inductors are used then they will attenuate the differential mode signal. If the inductor is wound , preferably bifilar, common mode then it will not attenuate the signal up to typically 1GHz but will attenuate the C/M currents. However some reduction in C/M currents on all the signal lines can be achieved by connecting the noisy digital ground to a clean, typically chassis, ground, as shown in figure 10b.

If the noise currents are predominantly C/M then a common mode choke, sometimes referred to as a balun, are available in many different configurations. It is important to use a balun that has a high impedance at the frequency/ies of concern and here the correct ferrite material, or a multiturn choke must be chosen. If a multiturn component is used then the impedance will reduce above its resonant frequency.

Although figures 10b to 10d indicate that C/M currents disappear, in practice they only reduce with these circuit configurations.

If the signal lines are in a cable external to a shielded enclosure the connection to chassis/enclosure ground in figures 10b and 10c should be as close to the point where the cables exit the enclosure as possible.

Figure 10a to 10d LC filter on a PCB with a noisy digital ground.

12) All conductive coatings are equal. Even a carbon based coating will be effective.

Many manufactures quote shielding effectiveness of conductive coatings only for E fields, which are very easy to shield against. Even a low conductivity (high resistance) coating such as carbon may be effective against an E field. In reality it is often required to achieve plane wave and magnetic field attenuation and here a high conductivity coating is required. Reference 4 compares the performance of pure metal plating, conductive paints and conductively loaded plastic and shows that the difference in magnetic field shielding between different products is very large.

13) Adding a ferrite toroid or bead (balun) to a cable will always reduce any RF current flowing on the cable.

If no current probe is available adding a ferrite on a cable is often used as a diagnostic tool to determine if RF current is flowing as well in EMI mitigation to reduce the current.

If a cable is electrically long ( greater than ½ wavelength) then the current on the cable is maximum at some location and zero at another. The high current location has a low impedance and the low current a high impedance. If a ferrite balun is placed on the low impedance section then any RF current within the frequency range of the ferrite will be reduced due to the impedance of the ferrite. However when placed at a high impedance section the current will not be reduced. Therefore move a ferrite up and down the cable to ensure that a low impedance section is found.

If the RF frequency is 50 MHz to 250MHz then a #28 material ferrite presents the highest impedance. If between 8MHz and 50MHz a #33 and for 200MHz and above a #25 Material.

Some ferrites are effective in the 1-2GHz range. For frequencies below 5MHz and especially around 100kHz a high permeability material such as a W material, which has a relative permeability of 100,000 may be useful.

A ferrite on a cable or wire also acts as an effective receiving antenna. If a ferrite is located on a PCB close to a source of high level RF , such as a clock oscillator, switching power supply or digital Ics the fields generated by these devices may couple to the ferrite and inject current into the cable and wire and then adding the ferrite is counterproductive.

If C/M RF current flows on a number of wires or cables in close proximity to each other then baluns are required either on each conductor, including signal and power grounds or overall. A common mistake is to put the dc power through one balun and the return through another. The resultant D/M current can saturate the ferrite. When signal and returns are placed through the same aperture in the ferrite the balun will not attenuate D/M signals up to 1GHz. However when the signal is routed through one hole in a two hole balun and the signal return through another attenuation of the signal is seen at much lower frequencies.

REFERENCES

- Electromagnetic Compatibility: Principles and Applications. D. A. Weston. Published by Marcel Dekker. 2001.

- 150Hz to 1MHz magnetic field coupling to a typical shielded cable above a ground plane configuration.

Report on www.emcconsultinginc.com. - An explanation of the “magic” low frequency magnetic field shielding effectiveness of conductive foil with a permeability of 1.

Report on www.emcconsultinginc.com. - Comparative magnetic field shielding effectiveness of thin conductive coatings.

Report on www.emcconsultinginc.com - Electromagnetic Compatibility Handbook . K.L. Kaiser CRC Press 2005. Section 23.1 page 23.1.

- PCB Electromagnetic radiation due to high speed logic from different layouts.

Report on www.emcconsultinginc.com. - How much better is a practical stripline PCB layout than a microstrip?

Paper presented at the Asia Pacific EMC Symposium May 2008 - Seams as the weak link in E field and plane wave shielding effectiveness.

Report on www.emcconsultinginc.com. - A study of Electric Field behind Isolated Metal Plate in a Radiated Immunity Test Set Up IEEE 2017 Electromagnetic Compatibility magazine Volume 6 Quarter2